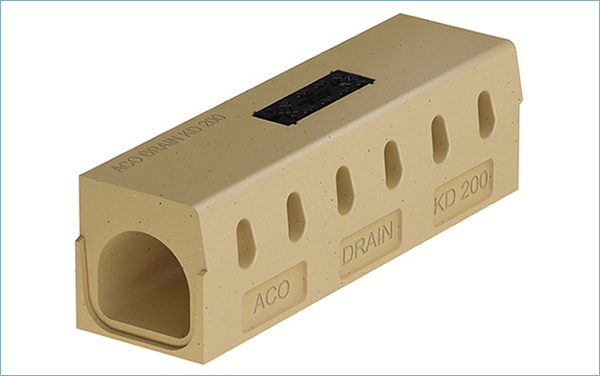

Ein wichtiges Kriterium für den Einsatz des Werkstoffs Polymerbeton im Tunnel ist die Klassifizierung „nicht brennbar“. Bauelemente im Tunnelbau unterliegen höchsten Sicherheitsanforderungen gemäß der europäischen Tunnelrichtlinie 2004/54/EG und den deutschen Richtlinien und Vorschriften RABT und ZTV-ING. Die Polymerbeton-Sondermischung von ACO erfüllt diese Vorgaben. Im Havariefall, insbesondere mit brennbaren Flüssigkeiten, wird auslaufendes Gefahrgut auf kürzestem Weg von der Straßenoberfläche durch die Tunnelentwässerung in den Untergrund geleitet und damit von der Sauerstoffzufuhr getrennt. Die Tunnelprodukte werden objektbezogen entsprechend den Anforderungen und Gegebenheiten ausgewählt und bieten so einen größtmöglichen gestalterischen und planerischen Freiraum. Die ACO Polymerbeton Sondermischung ist der erste Polymerbeton, der die Brandklasse A2-s1, d0 „nicht brennbar“ nach DIN EN 13501-1 erfüllt. Für den Tunnel erforderliche Expositionsklassen nach DIN EN 206-1 und DIN 1045-2 werden durch den ACO Polymerbeton mehr als erfüllt.

Regelwerke:

- europäische Richtlinie 2004/54/EG

- deutsche Richtlinien RABT und ZTV-ING

Wie muss eine Rinne beschaffen sein, um den RABT und den ZTV-ING zu entsprechen?

Was bedeutet der Havariefall für die Aufnahmekapazität des Entwässerungssystems?

Was passiert mit Flüssigkeiten in der Entwässerungsrinne?

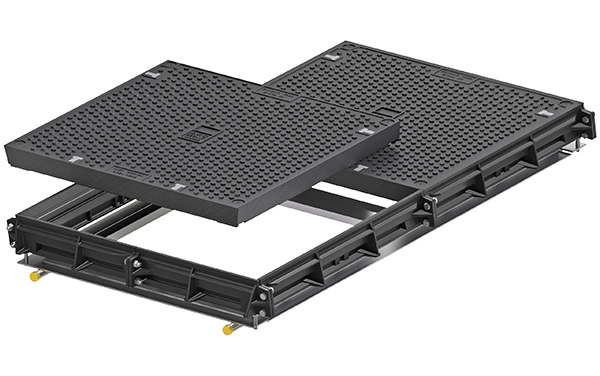

Wie ist die Umsetzung des sicheren barrierefreien Zugangs zum Fluchtweg?